Our HARO SYSTEM Service for You

Service from your "Knowledge Broker" means:

Our service as "Knowledge Brokers" in the printing industry plays a crucial role by going far beyond the traditional sale of printing machines and accessories. For our customers, this means a range of benefits that affect both their operational efficiency and their strategic alignment:

- Customized Solutions: By understanding the specific needs and challenges of their customers, Knowledge Brokers can offer tailored solutions that are precisely aligned with the requirements of the respective operation. This ranges from selecting the right equipment to optimizing production processes and implementing innovative printing techniques.

- Optimization of Production Processes: Knowledge Brokers assist customers in making their production processes more efficient. By analyzing and optimizing workflows, they can help shorten throughput times, reduce material waste, and increase overall efficiency.

- Risk Minimization: Through their expertise, Knowledge Brokers can help customers minimize investment risks. They provide insights into the reliability and performance of various machines and technologies, which helps customers avoid costly misinvestments.

Overall, our service as a Knowledge Broker in the printing industry provides our customers with significant added value by not being limited to sales but acting as a strategic partner that helps enhance operational performance and secure long-term business success.

Maintenance and Repair of Printing and Processing Machines

"Maintenance and repair of printing and finishing machines"

Preventive maintenance and the availability of first-class technicians in an emergency are extremely important factors for ensuring the production output of printing machines and other industrial machinery. We support you in the maintenance of your machines with motivation, flexibility and many years of industry-specific expertise.

The following services relating to the maintenance of your machines:

- Inspection and stocktaking in preparation for repairs and maintenance

- Professional troubleshooting, maintenance and repair work on your own or according to order (electrical, mechanical, electronic, pneumatic, welding)

- Support for your in-house maintenance with any assembly and maintenance work

- Regular preventive maintenance work according to the manufacturer's instructions or your maintenance schedule

- Holiday and sickness cover for your in-house maintenance team

"If the only tool you have is a hammer, you tend to see every problem as a nail."

Turnkey Relocation of Printing, Paper, Film, and Other Industrial Processing Machines

Professionally & Cost-Effectively with a Modular Approach

The relocation of printing machines and other industrial machinery requires a high level of technical know-how, organizational and planning skills, special tools and lifting equipment, as well as flexible, motivated, and experienced staff.

We offer you the best quality in all these areas, balancing attractive pricing with responsible calculation.

Our individually available services include:

Professional project and timetable planning, including CAD planning of the machine at the new location.

The final production test / acceptance of the machine before dismantling.

Assessment of the technical condition of the machine and suggestions for possible sensible repair, maintenance, or modernization measures.

Communication with the relinquishing company regarding project and timetable planning.

Professional securing of the production-critical machine software and possibly replacing buffer batteries of the machine control to ensure its functionality.

Professional mechanical, electrical, and electronic dismantling of the industrial plant, including written documentation of the individual dismantling steps.

Professional packaging, extraction, and loading of the dismantled machine elements in cooperation with selected regional packaging and loading specialists.

Preventive repair of individual sensitive electronic machine parts by specialists (maintenance & repair of machine control, hardware and software of the control PC, frequency converters / rectifiers, drive motors, etc.).

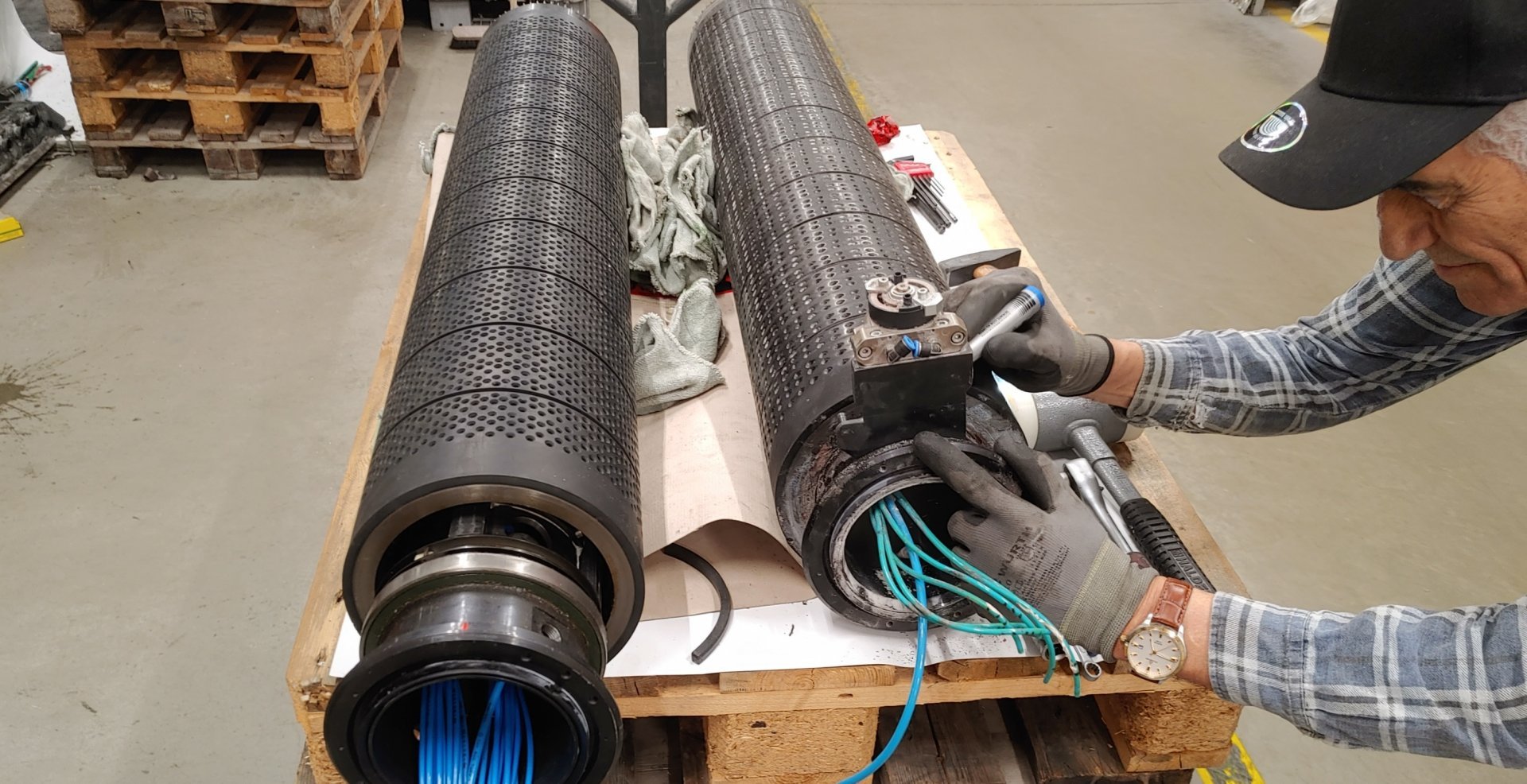

Re-rubberizing of printing rollers / recoating of friction and other rollers.

Transport in cooperation with selected machinery transport companies.

Preparation and inspection of the new machine foundation for the safe setup and anchoring of the machine elements (e.g., via fixators, air-loc shoes, or other machine shoes or pins).

Communication and coordination of the setup with your suppliers for electricity and media supply, media disposal, piping, galleries, (sound) protective walls, ventilation technology, refrigeration technology, paper roll feeding systems (e.g., Patras), as well as coordination with (external) technicians for repairs, maintenance, and modernizations of the respective machine elements or additionally to be installed auxiliary units.

Unloading and bringing in the individual units at the new location in cooperation with selected regional loading and crane specialists (in cooperation with our employees).

Professional mechanical, electrical, and electronic reassembly of the units until the entire production line is fully operational.

Professional maintenance & repair of the individual units as needed and by arrangement.

Troubleshooting any occurring errors and fault messages.

Electrical, electronic, and process engineering commissioning by specialists (e.g., for the dryer, for calibrating the blanket washing system to determine the Lower Explosive Limit (LEL)), commissioning of the roll changer, the printing units, the dryer, the gluing and adhesive device, the cut and color register control, as well as inline color measurement of the folding unit/folder, process engineering commissioning by a print master up to the final acceptance / final production test and establishment of commercial production capability.

Production monitoring & staff training, as needed.

We transparently explain the respective steps along with their associated costs. You are welcome to carry out individual steps yourself or provide your own staff if needed.

Flexible and Intelligent Solutions for the Trade & Maintenance of All Common Printing and Processing Machines and Everything Related to Sheeter Technology

We support you in planning and implementing your investments in machines for the production, processing, and finishing of web materials such as paper, cardboard, film, overlay, plastic, copper, aluminum, and many other substrates. Our services are aimed at printers, converters, paper and film manufacturers and processors, packaging companies, and the corresponding machines.

In addition, we provide all related technical services (audits, maintenance, repair, modernization, relocation, installation, commissioning & optimization, staff training, etc.) and procure a very large selection of spare and wear parts for your machines, as well as many obsolete/discontinued electronic parts and controls that can no longer be obtained from the OEM (Original Equipment Manufacturer).